As part of its continuous development by Transvalor, DIGIMU® benefits from the DIGIMU® Chair, managed by Armines MINES ParisTech and co-funded by ANR and an industrial consortium including ArcelorMittal, Framatome, ASCOMETAL, AUBERT & DUVAL, CEA, and SAFRAN. The consortium also involves Timet, Constellium, and Transvalor. DIGIMU® stems from over a decade of research at CEMEF, leveraging experimental data and advancements in numerical methods to maintain its leading position in metallurgy, aeronautics, and nuclear sectors.

DIGIMU® is the result of research projects conducted for more than ten years at the CEMEF (Material Forming Center) in collaboration with many industrial stakeholders from the metallurgy, aeronautics and nuclear sectors. The two pillars of DIGIMU® software development are the extensive experimental work and the constant improvement of existing numerical methods, which allow CEMEF to be at the forefront of world research in the field.

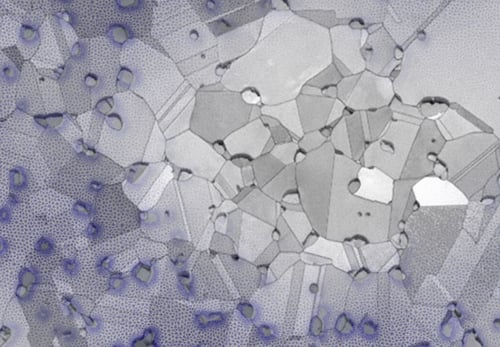

Microscopy of a nickel-based alloy carried out by the MSR group, CEMEF MINES Paris-Tech

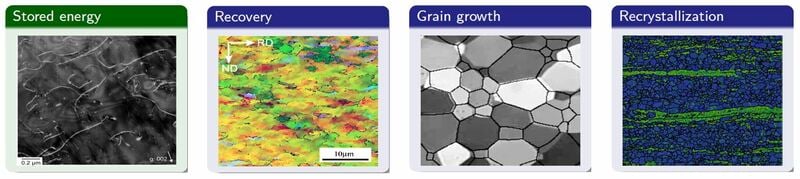

The full-field approach proposed by DIGIMU® has two main objectives:

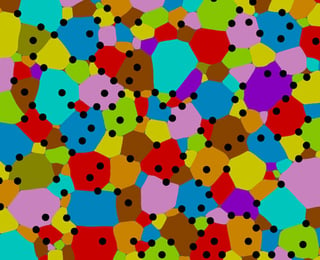

DIGIMU® generates digital polycrystalline microstructures representative of the material's heterogeneities (compliance with the topological characteristics of the microstructure). The boundary conditions applied to the REV are representative of that experienced by a material point at the macroscopic scale (thermomechanical cycle of the considered point). Based on a Finite Elements formulation, the various physical phenomena involved during metal forming processes are simulated (recrystallization, grain growth, Zener pinning due to second phase particles, etc.).

Anisotropic mesh adaptation used when no precipitation or nucleation occurs. Only the grain and particles boundaries are finely discretized.

Model CDRX, for example in aluminium alloys

In high stacking fault energy materials, the consideration of progressive formation and evolution of subgrains is essential. Dislocations could rearrange to form new low-angle grain boundaries (LAGB) or accumulate into preexisting LAGB. In the CDRX context, grain formation is induced by the progressive reorganization of dislocations into subgrains with a progressive increase in the misorientation angle between these subgrains. Based on the Gourdet-Montheillet model, incorporated to the LS-FE framework, a new full-field CDRX module was implemented in DIGIMU®. Now you can monitor recrystallization as your material deforms. You can also couple CDRX to an evolving population of SPP!

Other improvements

In the short term:

Predict, qualify, and quantify metallurgical changes at the mesoscopic scale. With DIGIMU®, you’ll receive support from the best partners in the advanced material technology industry. Through the DIGIMU® chair, you’ll have access to the latest technologies.

Our software provides assistance in the development of high performance alloys and parts through the prediction of microstructural phenomena.

.jpg?length=500&name=industrie_side%CC%81rurgie%20(1).jpg)

DIGIMU® allows to understand which metal alloys to use and the impact of the treatments applied to them.

.jpg?length=500&name=industrie_energie_vent-(1).jpg)

Simulation helps to control industrial risks related to the microstructure of the materials and their applications.

Anticipate your grains size driven by capillarity forces, and stored energy gradient at the interfaces.

Simulate polycrystal deformations, hardening and recovery, nucleation, and following nuclei growth. Follow static, dynamic and postdynamic recrystallization.

Import your models to define your own hardening, recovery and nucleation laws.

Let’s work together hand in hand. DIGIMU® users get the support they need when using our software.

World leader in software for simulation of material forming processes.