FORGE® is a forging simulation software dedicated to the simulation of hot and cold forming processes. It has been the flagship product of Transvalor for almost 35 years and is used by customers throughout the world. FORGE® fulfills the needs of companies producing forged parts for a variety of industrial sectors.

FORGE® software has unique features such as point tracking to easily detect any cold-shut areas in the part and to predict metal fibering which is essential to ensure that forgings possess good mechanical properties. Innovative marking techniques allow to materialize the segregations located in the center of the billet or to identify flow-through defects.

FORGE® incorporates several damage criteria that can be enabled to detect critical areas on the part.

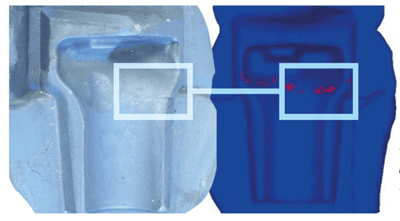

Fold/lap analysis: accurate folds/laps prediction of a mining steel component.

Fold/lap analysis: accurate folds/laps prediction of a mining steel component.

Fold/lap area is shown in red inside the frame.

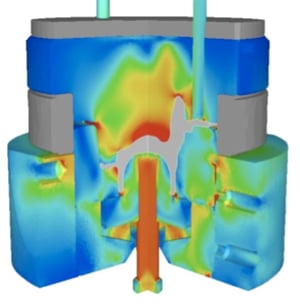

Tool life is a major challenge for which FORGE® predicts stresses, abrasive wear, temperatures and also areas subject to elastic or plastic deformation.

FORGE® predicts forging loads, energies consumed,torques and powers developed during each deformation operation. Then you can anticipate whether the effort required does not exceed the maximum capacity of your equipment, balance forging loads between the different stages and view die balancing and deflection problems.

Transvalor has been the first software provider to promote the concept of automatic optimization applied to material forming processes. Optimizing the starting billets to automatically improve yield or determining the ideal rolled preforms to ensure complete and defect-free die filling. Applied to forged components, automatic optimization allows the reduction of material costs by decreasing initial billet weight, do savings on energy cost by decreasing press load and extend die life by minimizing stress levels in the dies.

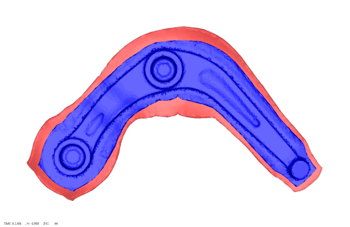

Optimization of the amount of flash.

Optimization of the amount of flash.

Before optimisation (red) and after optimisation (blue)

And many more

.jpg?length=500&name=industrie_automobile1-(1).jpg)

FORGE® is used by the largest manufacturers of forgings in the world for the automotive industry.

FORGE® is used by key producers worldwide to design engine parts such as pressure disks or fan disks or fans, landing gears, fuselage parts, etc.

.jpg?length=500&name=industrie_medical-(2).jpg)

Our simulation software is an essential and strategic tool for the development of medical devices with high added value.

Develop and validate the entire induction hardening process for rack bar components, covering both the teeth and the side of the part.

The project initiated by creating a 3D CAD model for a complex rack bar and collecting material properties. Validation of 3D FEM models involved comparisons of heat-affected zones, martensite phase distribution, and hardness profiles.

"Accurate modelling of our in-house induction hardening process will open the doors to improving efficiency and reducing costs within our organization. With validated models, we will be able to cut-down on scrap and energy costs by achieving “right -first-time” results. Additionally, this approach will facilitate ongoing improvements through the design and comparison of new coil geometries, ultimately aiming to enhance both our process and the quality of the end product."

To opt for Transvalor is to trust the expertise of the teams and the excellence of the products, which have been a step ahead for its customers for more than 35 years.

READ THE TESTIMONIALS >

Results that perfectly reflect reality to produce high-quality parts from the first batch. Stable and efficient remeshing capabilities with tetrahedral elements perfectly adapted to the successive and intensive remeshing.

Parallel computing is available for all processes and is compatible with all options. FORGE® keeps an almost constant efficiency for calculations launched on a large number of cores. READ MORE >

Simulate all the operations required to manufacture your part, from furnace or induction billet heating, through all stages of preforming and forging to final operations (trimming, punching and heat treatment).

World leader in software for simulation of material forming processes.